Our new Gen 2 TechTilt concrete walls are fire, flood and pest resistant inside and out

For those of us drawn to building our dream home amidst the beautiful Australian outback, better protecting our family and property against the forces of nature could be easier by building with TechTilt‘s next generation wall.

Now available and soon to be used to construct two new homes in the Adelaide seaside suburb of Glenelg North, TechTilt developer Lou Gagliardi says the twin-wall concrete panel design makes it resistant to fire, flood and pests inside and out. It also offers unique features not found in other walling systems.

“I’ve seen houses go up over the years without much thought by some about how well they will stand up to the harsh Australian elements in the long term,” said Lou Gagliardi, CEO of TechTilt Building Systems.

“Frame and cladding walls have become the standard for new homes. They have a concrete-like external appearance, but while they are a barrier to the elements, when the air- conditioner goes off, the temperature changes back quickly.

“It takes longer for the heat of the sun or the cold to get through our new generation TechTilt walls than it does for standard walls. And because of the thermal mass properties of concrete, the internal TechTilt walls will absorb whatever heating or cooling you have on in the home and radiate it back. In a way, it plays a very active role in regulating the temperature of the house inside, keeping it stable in the comfort zone.

“Giving people another choice is what inspired me to develop the TechTilt system and to evolve the design further in our next generation wall,” Lou said.

Smart features make the TechTilt system fast to build with and solves one of the problems of solid concrete construction – adding or moving services (power, data and plumbing) after the home is built.

“Any builder will tell you that the availability of trades and weather delays can have an enormous knock on effect in scheduling, and on the finish date. So my approach to designing TechTilt was to reduce the number of steps and trades required,” he said.

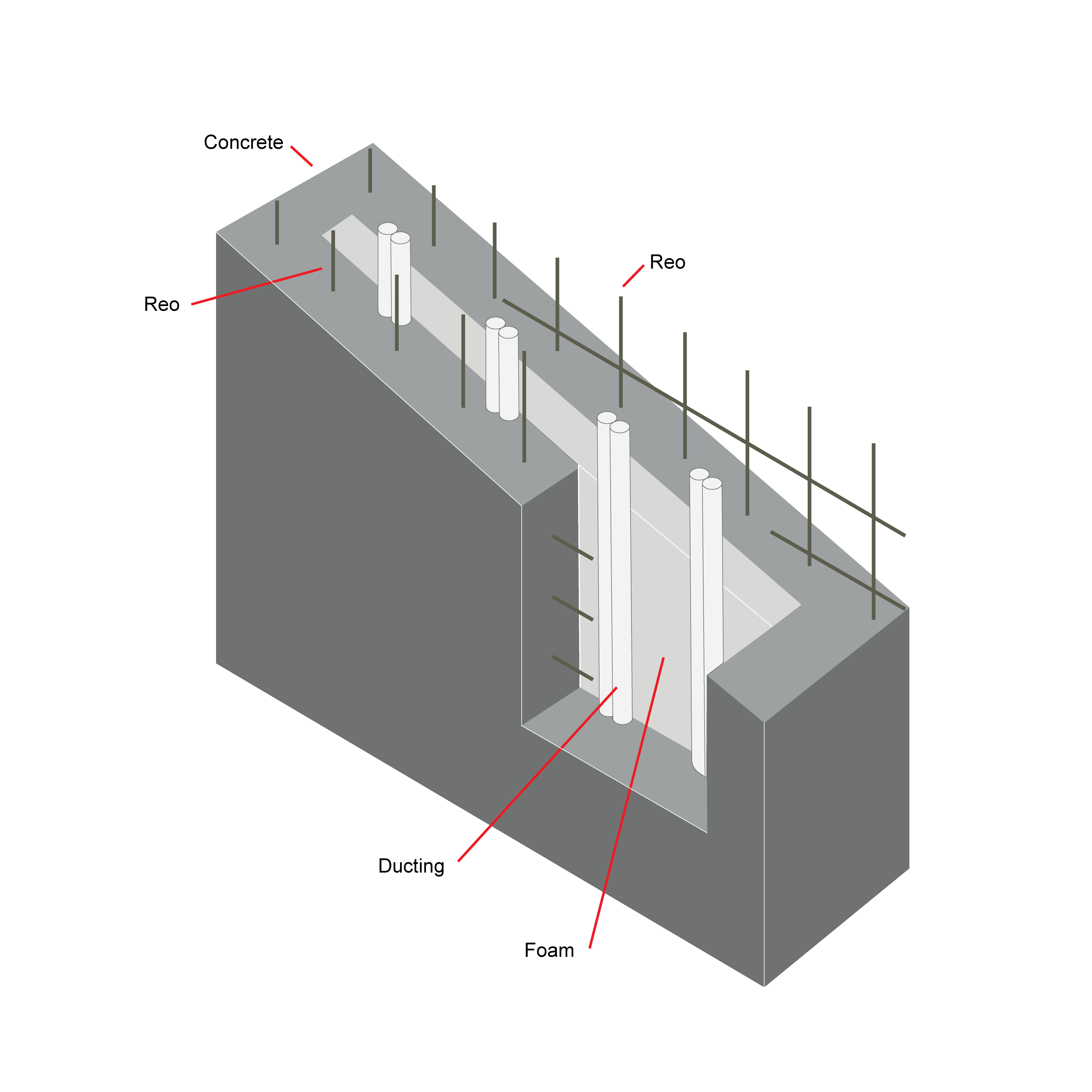

“TechTilt walls combine four steps in the traditional building process into one. You don’t need a timber or steel frame – that’s one step saved. High density insulation is built in – that’s another step saved. And both the internal and external walls are fully complete – saving on both cladding outside and finishing the wall off internally with plasterboard.”

“The same service channels people love in our Generation 1 wall are also in my new design. Multi-chamber conduits safely house plumbing, data and electrical, are included as standard every 300mm along each wall, making it easy to move or add services and when used for commercial buildings, to refit spaces for new tenants.

“Most importantly of all, because each side of our new wall is solid concrete, it will be stronger and more able to keep everyone inside comfortable given Australia’s harsh climate, than the standard type of home we see built in our modern times.

TechTilt walls can be built on site from local materials which is good for those living in remote areas and those who wish to lower their carbon footprint. They can also be made in a factory and transported if desired.

To learn more about the Generation 2 TechTilt walls, download the product specification sheet or call Lou Gagliardi on 0429 706 579.